FLUIDRA – Circular Diagnosis of Products and KPIs’ definition

Client: Fluidra

Project: Circular diagnosis and KPIs’ definition to align ESG Products to Fluidra’s ESG strategy.

Date: January 2022, in progress

Context: Fluidra, the world leading company in pools and wellness products, is committed to ensuring that 80% of its product sales are classified as “ESG Friendly Products” by 2035. The company knows that their products have the greatest impact on climate, accounting for more than 90% of the overall company’s impact. To address this, Fluidra’s R+D department takes the lead, in collaboration with EIG and Lúcid.

EIG’s role:

Assess products and processes, together with their supply chain, in terms of material health, design for circularity, and environmental impact along the whole life cycle. Guide in the understanding of circularity scalability potential from these pilot projects to the company. Definition of the KPIs to monitor and identify ESG products in Fluidra’s catalogue

Goals:

Circular Diagnosis:

Understand the circular potential through a pilot project and identify strategies for improvement at product, business and operations levels.

The purpose of the Circular Diagnosis is to know the starting point and to visualize where you are heading; it means to understand where you start from, what you have, what your opportunities and strengths are and also the weaknesses you need to focus on to improve.

Goals inspired in the 5 requirement categories of the Cradle to Cradle Certified® Products Program:

• Material Health: Analyze materials to assess potential risks in terms of safe for humans and the environment.

• Circularity: Evaluate how to enable a circular economy through product and process design.

• Renewable energy and Carbon reduction: Analyse the critical points in terms of energy and climate protection.

• Water and soil stewardship: Study the use of resources such as air, water and soil with a life cycle perspective.

• Social Fairness: Analyse working practices, policies both in company and along the supply chain.

Project’s scope:

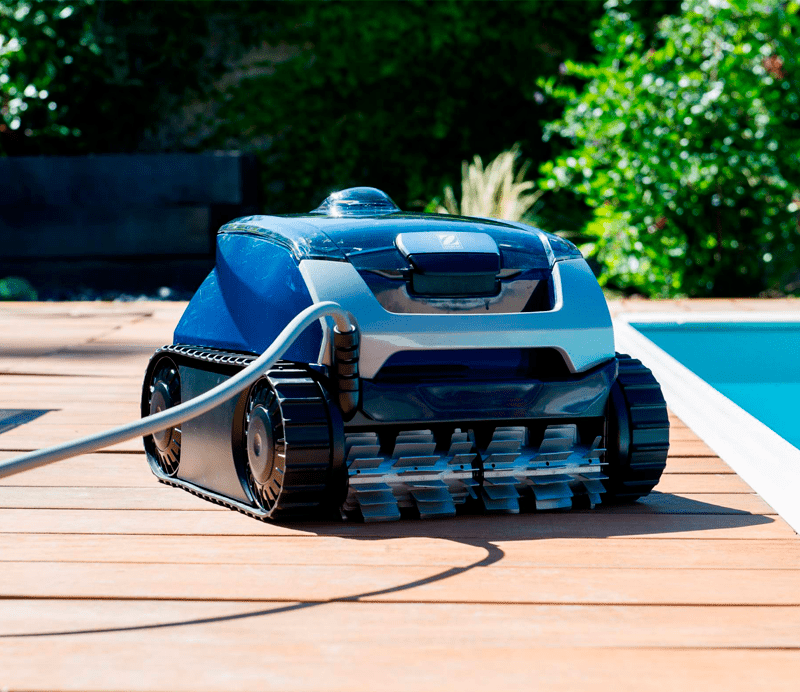

The project evolved as we moved towards the goal of developing the ESG Friendly products’ catalogue. It started with a pilot project carried out on 3 products (Robot Cleaner and Residential Pumps), developed in several stages. At the first stage we were focus on identifying hotspots and strengths:

- Data Collection

- C2C Pre-assessment: applying the Cradle to Cradle® approach and the Cradle to Cradle Certified® Products Standard as a framework to analyse the product

- Life Cycle Assessment to understand the environmental impacts in the different phases of the products’ life cycle

In a second stage, we worked on the metrics to unedrstand products’ performace against company’s goals by:

- Alignment with Fluidra ESG Strategy (development of the set of KPI’s to define and standardise the criteria)

- Transfer knowledge by training teams internally

- Optimization matrix to move forward with the pilot projects

Main challenges:

-

Traceability

Improvement of the internal knowledge of the product, its materials and the supply chain to reach a molecular traceability level.

-

Circular transformation

Identify the barriers and opportunities of product design in order to implement circular business models.

-

KPIs definition

Matching the KPIs definition with the ESG corporate strategy and the marketing needs.

-

Global commitment

Internal engagement of the different teams involved both at R+D and product design areas. Knowledge transfer to other departments.

What’s next:

Diagnosis is the first stage, but having a positive impact is the goal made possible through a real transformation. The next steps will be to design an action plan and monitoring strategy to proceed with the implementation of the improvement that were detected in the pilot. This will unfold new discoveries that will feed the continuos improvement path; therefore, enabling the innovation and transfer to other products.

KNOW: Circular Diagnosis –> PLAN: Pilot projects / KPI definition / action plan–> MAKE: Training / Testing